"The waste sector plays a pivotal role in enabling a circular economy, ensuring waste is minimised and resources are re-used and recycled in the best possible way."

"The waste sector plays a pivotal role in enabling a circular economy, ensuring waste is minimised and resources are re-used and recycled in the best possible way."

The first sod was turned on Friday 5 February on a $45 million plastic pelletising facility being built by a joint venture of Cleanaway, Pact Group and Asahi at Albury in NSW, which will be able to recycle more than one billion bottles per year.

“This new facility for PET plastic will recycle the containers collected through the NSW Return and Earn Scheme and Cleanaway’s Material Recovery Facilities, helping create a domestic circular economy,” Cleanaway’s CEO and Managing Director, Vik Bansal, said.

Pictured from left to right: State Member for Albury, Justin Clancy, Asahi Beverage’s Group CEO, Mr Robert Iervasi, Cleanaway’s CEO and Managing Director, Mr Vik Bansal, Pact’s Managing Director and CEO, Mr Sanjay Dayal, Environment Minister and Federal Member for Farrer, the Hon. Sussan Ley MP

Only days earlier the Federal and Western Australian governments announced a $9.5 million grant from the $190 million Recycling Modernisation Fund for a plastic recycling facility planned in Perth by Cleanaway and Pact under the Circular Plastics Australia (CPA) joint venture.

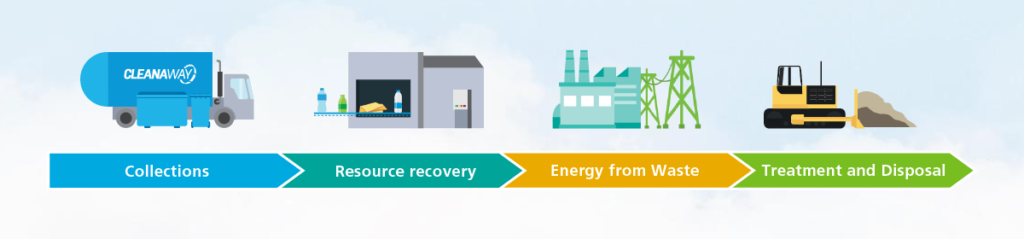

These milestones marked the continued extension by Cleanaway of the waste value chain which extends from collections, through resource recovery and energy from waste, to treatment and disposal in landfill.

By reprocessing commodities recovered from waste, like plastic, glass, paper and cardboard, we extend the value chain beyond sorting to create long term value for recycling.

Cleanaway has invested more than $500 million in growth projects, including collection, sorting and processing infrastructure, since FY16.

This includes greenfield developments such as the original Perth Materials Recovery Facility (MRF), transfer stations and resource recovery facilities, and landfill biogas generators to recover to energy from landfill gas.

In addition, the company acquired SKM Recycling Group’s resource recovery assets and industrial services and waste management business Toxfree Solutions for more than $700 million in total.

More capital investment is planned in coming years, including CPA pelletising and recycling facilities, potential energy-from-waste facilities in Melbourne and Brisbane, and improved landfill engineering and technology in Melbourne, Adelaide and Queensland.

“These greenfield and acquisition investments are part of our Footprint 2025 strategy to ensure we have the right infrastructure and technology across the waste value chain and can play our role in sustainably meeting Australia’s waste needs and contributing to the creation of a circular economy,” Vik said.

“The waste sector plays a pivotal role in enabling a circular economy, ensuring waste is minimised and resources are re-used and recycled in the best possible way.”

“This requires significant investments in new infrastructure and a change in the way we think about and deal with our waste.”

“As an important material, plastics represent a big opportunity which is why we are investing in this space.”

Vik said Cleanaway was focused on collecting, sort and reprocessing four key polymers: high density polyethelene (HDPE), polyethylene terephthalate (PET), low-density polyethylene (LDPE) and polypropylene (PP), which represent 54 percent of Australian plastic consumption.”

The material is collected from Cleanaway’s 100-plus council and 140,000-plus commercial customers using its fleet of more than 400 recycling vehicles, along with container deposit schemes (CDS) in NSW, Queensland and Western Australia.

For instance, TOMRA Cleanaway, the joint venture with global reverse vending technology leader TOMRA, in is the network operator in the highly successful NSW CDS, with more than five billion containers returned and $430 million refunded to customers and charities since the start in December 2017.

“To enable the development of a circular economy for plastics in Australia we need to improve the quality of material that is available for recycling, and develop reprocessing technology on-shore so that material can be sent direct to recyclers for manufacturing,” he said.

“We also have to improve the quality of materials that go into the recycling bins through the introduction of harmonised multi-bin collection systems, with standardised rules and lid colours to help education across jurisdictions, and then monitoring of compliance levels to correct contamination issues.”

“With reduced access to export markets we need to generate demand for recycling content in manufacturing on-shore so that we can truly close the loop on plastic.”

Contact us to learn more about how we’re making a sustainable future possible.