Since our contract began, we have developed bespoke solutions for waste streams inclusive of scrap metal and glass recycling at Prendiville’s wineries.

Since our contract began, we have developed bespoke solutions for waste streams inclusive of scrap metal and glass recycling at Prendiville’s wineries.

Cleanaway is proud to be providing The Prendiville Group, one of the largest owner-operator hotel groups in Australia, with comprehensive waste management services across 21 locations. Our tailored service includes general and bulk waste collection and disposal, commingled and green waste collection and recycling, as well as grease trap cleaning services.

Cleanaway’s service provides a single point of contact for multiple locations and waste streams that allow Prendiville to focus on what they do best – providing unforgettable hospitality through its facilities.

Cleanaway Key Account Manager Joanna Laughton said, “As home grown Australian owned and operated businesses, Cleanaway and The Prendiville Group are committed to make a positive difference for our employees, customers, the communities where we work, and the planet.”

“It’s Cleanaway’s job to match Prendiville’s premium customer experience not only with discreet and reliable servicing but in the way we extend their sustainability brand. We have developed a tailored waste management strategy to recover as much recyclable material as possible and even improve the supply chain to minimise waste and environmental impact.”

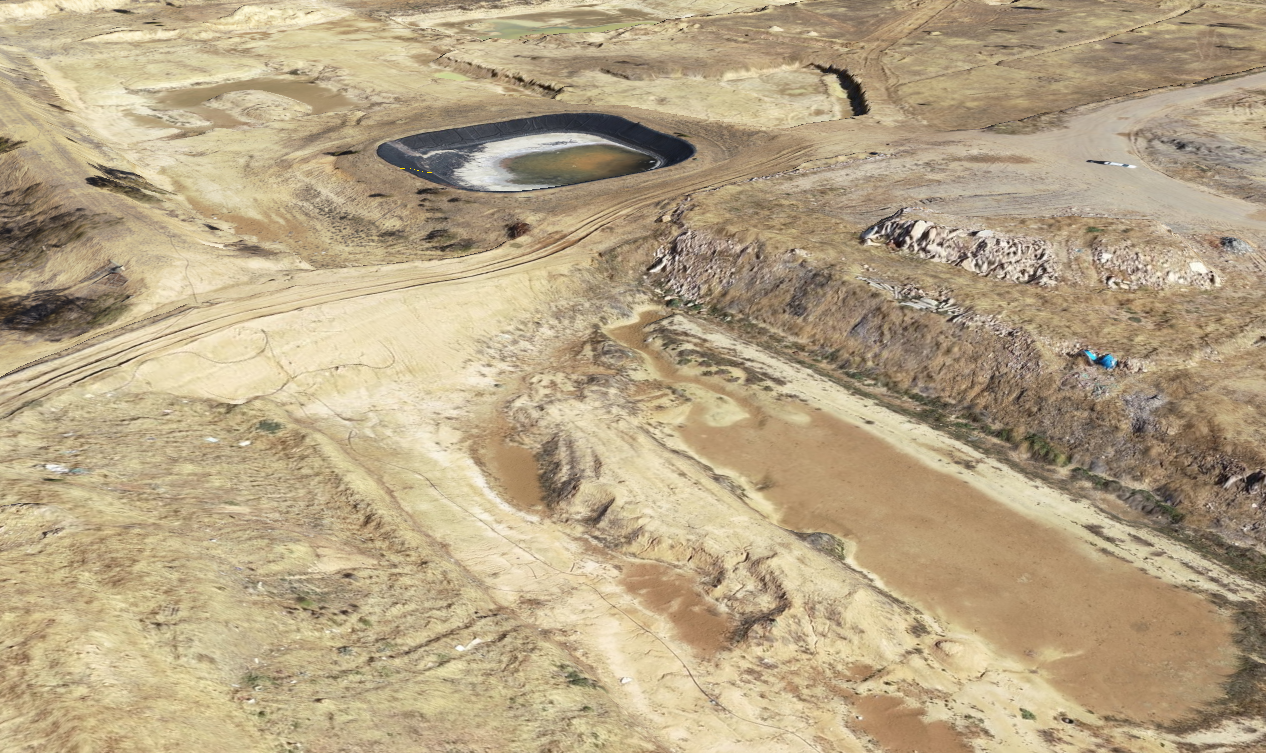

“Since our contract began, we have developed bespoke solutions for waste streams inclusive of scrap metal and glass recycling at Prendiville’s wineries. We look forward to working further with Prendiville to identify even more opportunities to increase landfill diversion.”

The Prendiville Group is a family-owned company established in 1983 providing unique travel experiences in some of Australia’s most iconic destinations, from beaches in Rottnest Island, vineyards in the South West, and red earth outback adventures in Karratha.

Cottesloe Beach Hotel

This hotel overlooks one of Australia’s most famous stretches of golden sand, The Cottesloe Beach.

Tradewinds Hotel

Located on the beautiful Swan River, the Tradewinds Hotel is a short thirty minutes from the Perth CBD and a stone’s throw from the vibrant streets of Fremantle.

Pier 21 Fremantle

Nestled on the banks of the Swan River is the highly regarded Pier 21 Apartment hotel.

Hotel Rottnest

Hotel Rottnest is an idyllic holiday destination in Rottnest Island.

Norfolk Hotel Fremantle

Soak up Fremantle’s eclectic and vibrant culture at the Norfolk Hotel. This hotspot is within walking distance to all of Fremantle’s famous tourist attractions.

Sandalford Wines Swan Valley

Sandalford’s estate at Caversham, Swan Valley had its beginnings in 1840 and coincided with both the European settlement in the burgeoning colony of Perth and the birth of Western Australia’s world famous wine industry.

Brisbane Hotel

The Brisbane Hotel is located at Perth’s hippest thoroughfare and features quality fresh cuisine, premium wines, innovative design, a lush terraced beer garden and outstanding service.

Regional hotels

The Prendiville Group also operates facilities in regional WA including Mangrove Hotel in Broome, Continental Hotel Broome, Karratha International Hotel, Ibis Styles Karratha, Hedland Hotel in Port Hedland, Ibis Styles Katherine, Ibis Styles Mt Isa, Ibis Styles Kununurra, The Plaza Hotel Kalgoorlie, Ibis Geraldton and the Grand Hotel Townsville.

For more unique venues and information visit https://www.prendiville.com.au/

Contact us to learn more about our total waste management services for the hospitality sector.