Innovative solutions for hard to abate emissions in heavy vehicles

Transitioning Australia’s heavy vehicle industry to zero, or low emissions technology is essential to achieving our own and the Australian Government’s climate targets. This transformation will require a diverse range of solutions for different services and fleet types. Cleanaway is fully committed to driving this progress and investing in the technologies needed to achieve sustainable outcomes.

HVO100 renewable diesel

Cleanaway is pioneering the drop-in fossil fuel replacement, HVO100, as a renewable option for the heavy vehicle industry. Cleanaway’s Head of Innovation, Jeroen Wassenaar, presented at the All Energy Australia conference providing an update on our demonstration.

The demonstration with two collection trucks started in February 2024, and in June we released a comprehensive mid-way update . These initial results indicated that HVO100 provides equivalent fuel consumption, uptime and performance compared to fossil diesel.

Now that the demonstration has been completed, we can share the complete data showing the equivalent fuel consumption compared to fossil fuel and further evidence that HVO100 runs cleaner.

Equivalent fuel consumption

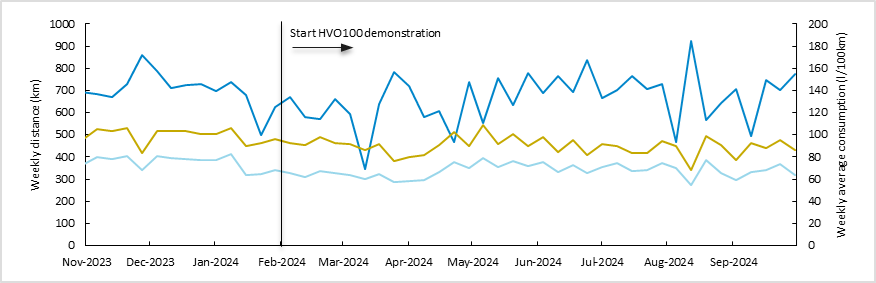

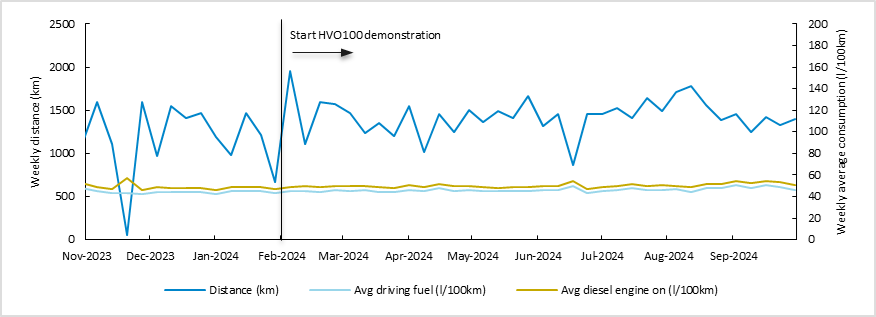

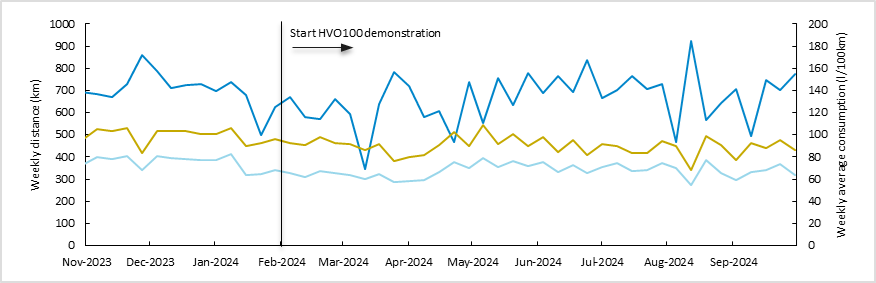

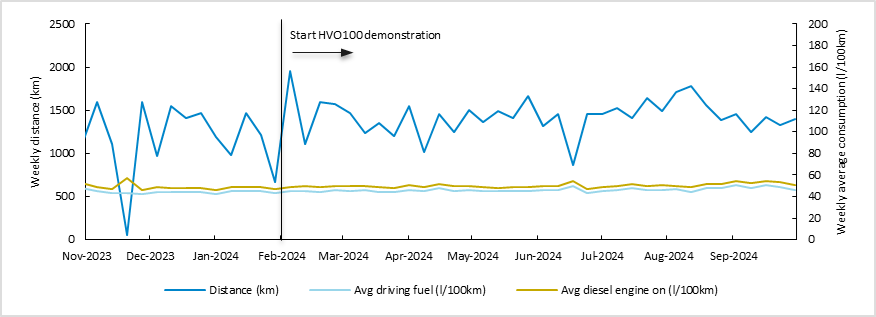

Fuel consumption was closely monitored in both trucks through Volvo Connect aa depicted in the graphs below. Measurements started already 3 months prior to the demonstration when both trucks were still running on fossil diesel allowing a comparison of fuel consumption between fossil diesel and HVO100.

The demonstration involved two Volvo trucks with different engines, configuration and duty. The sidelift truck serviced the City of Casey, picking up kerbside commingled recyclables from households and its route is characterised by very frequent starting and stopping leading to a relatively low mileage but high fuel consumption. The frontlift truck collected Coles supermarkets organics. It covers much greater distances involving less stopping with consequently a lower fuel consumption.

The weekly average fuel consumption for both trucks before and during the HVO100 demonstration confirm that fuel consumption was equivalent between HVO100 and fossil diesel. This was further confirmed through feedback from the drivers who noticed no difference in power delivery.

In FY24, our fleet emissions constituted 20% of our Scope 1 and 2 emissions. The pathway to decarbonising our fleet will take time, but we are committed to leading our industry with innovative, fit-for-purpose solutions that align with our customers’ goals while working towards Australia’s emissions reduction targets.

Sidelift Volvo D8K320 Euro 6

Frontlift Volvo D11C410 Euro 5

Effect on fuel filters

The fleet maintenance team at our Perry Road depot in Victoria has been monitoring the effect of HVO100 on engine performance and taken a close look at the fuel filters upon replacement at regular maintenance intervals. Pictures of those filters after they were removed are shown below, both for the truck running on HVO100 and another identical truck fuelled with fossil diesel. Cleanaway’s National Fleet Repair and Maintenance Support Coordinator Danny Martin commented:” Although the filters from the HVO100 truck have had less mileage than the ones from the truck running on fossil diesel, they are still surprisingly clean. A lot cleaner than I would’ve predicted.”

Emissions reduction

HVO100 is a 100% renewable diesel made from renewable sources such as used cooking oil. It is near chemically identical to fossil diesel which means it’s a “drop-in” replacement requiring no new infrastructure, fleet, or additional capital. As it is made from renewable resources, all carbon in the fuel has been captured from the atmosphere that is released again upon combustion, resulting in net zero carbon emissions.

During the eight months of the demonstration, we used 46kL of HVO100 and saved 124 tonnes CO2-e compared to burning fossil fuel-based diesel; emissions savings are calculated using the 2023 National Greenhouse Account Factors provided by the Australian Department of Climate Change, Energy, the Environment and Water.

Hydrogen vehicles

As part of our strategic partnership with Viva Energy and their ambitious hydrogen mobility project, the Viva Energy Hub, Cleanaway recently received two hydrogen trucks to our site at Perry Road. The project seeks to develop infrastructure, industry expertise and on-road experience for hydrogen as a zero emissions option for heavy vehicles in Australia.

The Viva Energy Hub itself is anticipated to be ready for hydrogen fuelling in early 2025 and until then, Cleanaway will be focused on training our teams and identifying the right routes for these trucks. Once operational we’ll be tracking uptime, payload, performance in different terrain and overall running cost to contribute to the development of this important green energy solution.

The project received a $34 million grant from the Australian Renewable Energy Agency (ARENA) as part of ARENA’s Advancing Renewables Program and the Victorian Government also contributed $1 million to the project via the Renewable Hydrogen Commercialisation Pathways Fund.

Our trucks have already had to overcome some significant challenges with our hydrogen truck manufacturing partner, Hyzon, going into administration towards the end of the build. This speaks to the vulnerability of this emerging market in Australia, making it all the more important that we commit to demonstrations like the Viva Energy Hub.

In FY24, our fleet emissions constituted 20% of our Scope 1 and 2 emissions. The pathway to decarbonising our fleet will take time, but we are committed to leading our industry with innovative, fit-for-purpose solutions that align with our customers’ goals while working towards Australia’s emissions reduction targets.