We can all play a part in ensuring recycling outcomes are maximised by putting items in the right bins and helping avoid contamination.

We can all play a part in ensuring recycling outcomes are maximised by putting items in the right bins and helping avoid contamination.

Cleanaway’s 2024 Recycling Behaviours Report revealed that 2 in 5 Australians don’t trust that their waste will be properly recycled and 18 per cent incorrectly believe that everything just goes to landfill (and therefore nothing is recycled).

We’re here to explain the process materials undergo at our facilities and the new life they can take on.

The contents of the commingled or recycling bin is taken by Cleanaway to sorting facilities called Material Recovery Facilities (MRFs). There, items are separated by material – paper, cardboard, plastic, glass, steel, and aluminium.

Machinery such as optical scanners and conveyor belts are used alongside manual sorting by staff to separate different materials.

Once the sorting process is complete, the material is sent on to reputable onshore and offshore recyclers to be reused in manufacturing new products. Here, we explain what happens to each material, and the new life we can expect.

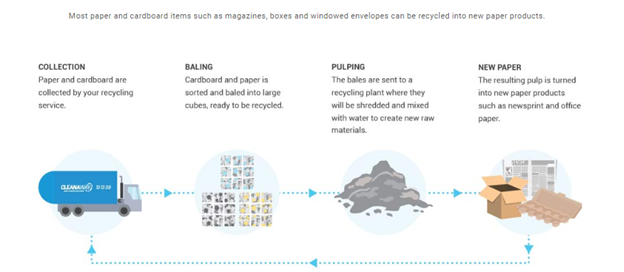

Paper recycling

Paper is shredded and mixed with water to create pulp, followed by de-inking, a process which removes ink from the original product. The pulp then goes on to be manufactured into new paper products.

You may have seen products such as printing paper, toilet paper, and cardboard packaging made from recycled materials available to purchase.

Plastic recycling

Plastics are shredded into pellets, which become the building blocks for new plastic items when used in the manufacture of new products.

Container Deposit Scheme’s across the country play a role contributing to ‘bottle to bottle’ recycling. The pellets, derived from the recycled bottles, are small plastic pieces that can be used to create new bottles from, such as those produced through Circular Plastics Australia (PET) a joint venture between Pact Group Holdings Ltd, Cleanaway, Asahi Beverages, Coca-Cola Euro-pacific Partners.

Aside from bottles, the pellets can also be turned into flakes where they can then produce other items such as polar fleece jackets and stationery.

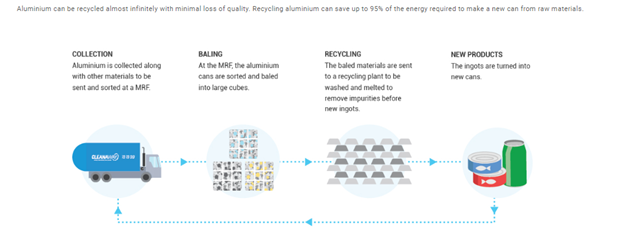

Steel and aluminium recycling

You might have aluminium cans at home and wonder what happens when they’re placed into a recycling bin with plastics, or returned via a Container Deposit Scheme.

Steel can easily be sorted from other recyclable materials with the help of industrial-scale magnets at facilities. Steel can be melted down at high temperatures, and paint and coatings are removed. They then become processed into ingots, which are blocks of pure material.

The recycled aluminium and steel ingots could be turned into a new can, or even used to make parts for cars and aeroplanes.

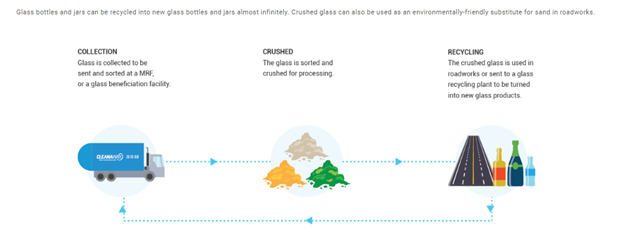

Glass recycling

Glass is often the last material to remain on a recycling conveyor belt for a variety of reasons.

Lighter materials are generally sorted first and being denser than many other recyclables like plastic and paper, it is easier to handle glass later in the process. Furthermore, glass can break easily and pose a safety hazard to staff, so specialist equipment is required.

Once separated from other materials, glass items such as bottles and jars are crushed at facilities and undergo a cleaning process to remove labels, caps and remaining liquids.

The glass is then melted at a high temperature and can be formed into new products such as glass bottles with high-grade material, and road bases with lower-grade material.

Outcomes

The above are examples of closing the recycling loop and helping work toward a circular economy in Australia, where needing to use new virgin materials is avoided.

Cleanaway is a big contributor to resource recovery in Australia, and in the 2023 financial year, we have recovered 431 kilo tonnes (kt) of paper, and 32 kt of steel and aluminium.

To give you an idea of the scale of these amounts, 1 kilo tonne = 1,000,000 kilos, or the weight of two and a half large commercial airplanes, showing the power of recycling correctly to preserve precious resources and prevent materials ending up in landfill.

We can all play a part in ensuring recycling outcomes are maximised by putting items in the right bins and helping avoid contamination.

Cleanaway’s Recycling Behaviours Report

For the fourth year running, Cleanaway and the Clean Energy Finance Corporation (CEFC) have conducted research into Australians’ recycling behaviours. These valuable insights on everyday recycling challenges help shape Cleanaway’s priorities when empowering Australians in their recycling decisions.

Since 2017, the CEFC has been working with Cleanaway to support waste education efforts, such as the Recycling Behaviours Report. Through this investment, Cleanaway and the CEFC aim to reduce waste going to landfill and create a sustainable future for Australians.