Melbourne Energy & Resource Centre

Melbourne Energy & Resource Centre

By 2046 Victoria is forecast to send an estimated 5.9 million tonnes of waste to landfill each year*.

That’s enough to fill almost 5,000 Olympic size swimming pools or 7.8 MCGs, every year. Cleanaway is committed to developing a sustainable alternative to landfill to manage residual waste.

We are excited to showcase this video highlighting the proposed waste-to-energy facility. The facility is designed to divert residual waste that would otherwise be sent to landfill. It will also enable the recovery of energy and valuable materials such as ash and metals. See how it works here!

Residual waste is the general waste we put in the bin after we have reduced, reused and recycled. It also includes residual commercial waste from industrial and demolition sources. Currently, all of Victoria’s residual waste is being sent to landfill for disposal.

Landfills take up vast areas of land and bury useful resources. The Victorian government is taking steps to increase the recovery of materials currently being sent to landfill such as Food Organics and Garden Organics, as part of the Victorian Government’s circular economy policy and plan. However, there will always be waste that cannot be avoided, reused or recycled. For that reason, the Victorian circular economy policy and plan acknowledge the role of waste to energy, for the recovery of energy and other resources from residual waste, through the Victorian Waste to Energy Framework. Cleanaway operates a range of recycling programs and facilities to divert waste from landfill. Through the MERC, Cleanaway is investing in a sustainable alternative to landfills for this residual waste.

*Source: Sustainability Victoria. 2022, September 16. Victoria’s Waste Projection Model.

We can divert landfill waste and transform it into valuable sustainable energy

Cities across Europe, America, Japan and many other developed countries use waste-to-energy facilities to recover energy and other valuable resources from material that cannot be recycled and would be destined for landfill. Cleanaway is proposing to build a waste-to-energy facility here in Victoria, using leading-edge technology that is proven.

Scroll down to read more about the proposed Melbourne Energy and Resource Centre (MERC).

Learn more and make a submission

Response to community submissions

The public submission and comment period for the Development Licence Application commenced on 20 February 2024 and closed 14 April 2024. In total, 763 submissions were received from the community and stakeholders during this period. Cleanaway has reviewed all submissions received, and a report has been prepared to respond to the key community and stakeholder themes. This report aims to assist the EPA and members of the public to better understand the Proposal. You can view the report here.

Response to Conference of Interested Persons Questions

The EPA convened a Conferences of Interested Persons, held on June 20 and June 25, 2024. Please see Cleanaway’s responses to some of the questions raised.

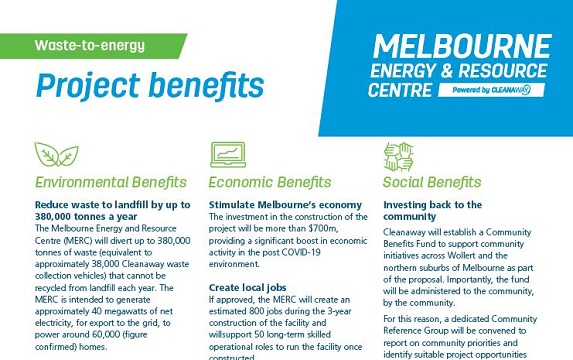

What are the benefits of MERC?

Is this safe?

Cleanaway is committed to developing safe facilities across Australia.

Our proposal will use international best practice technology to comply with Environment Protection Authority (EPA) Victoria’s standards for air emissions and the European Industrial Emissions Directive, which is based on decades of experience and safe operating practices.

99.9% of the flue gas produced will be gases common to air, including oxygen, carbon dioxide, nitrogen and water vapour. The remaining pollutants will be treated with modern technology to meet stringent emission limits.

We will be publishing air quality monitoring data on our project website on a regular basis.

Learn more about other waste-to-energy facilities overseas.

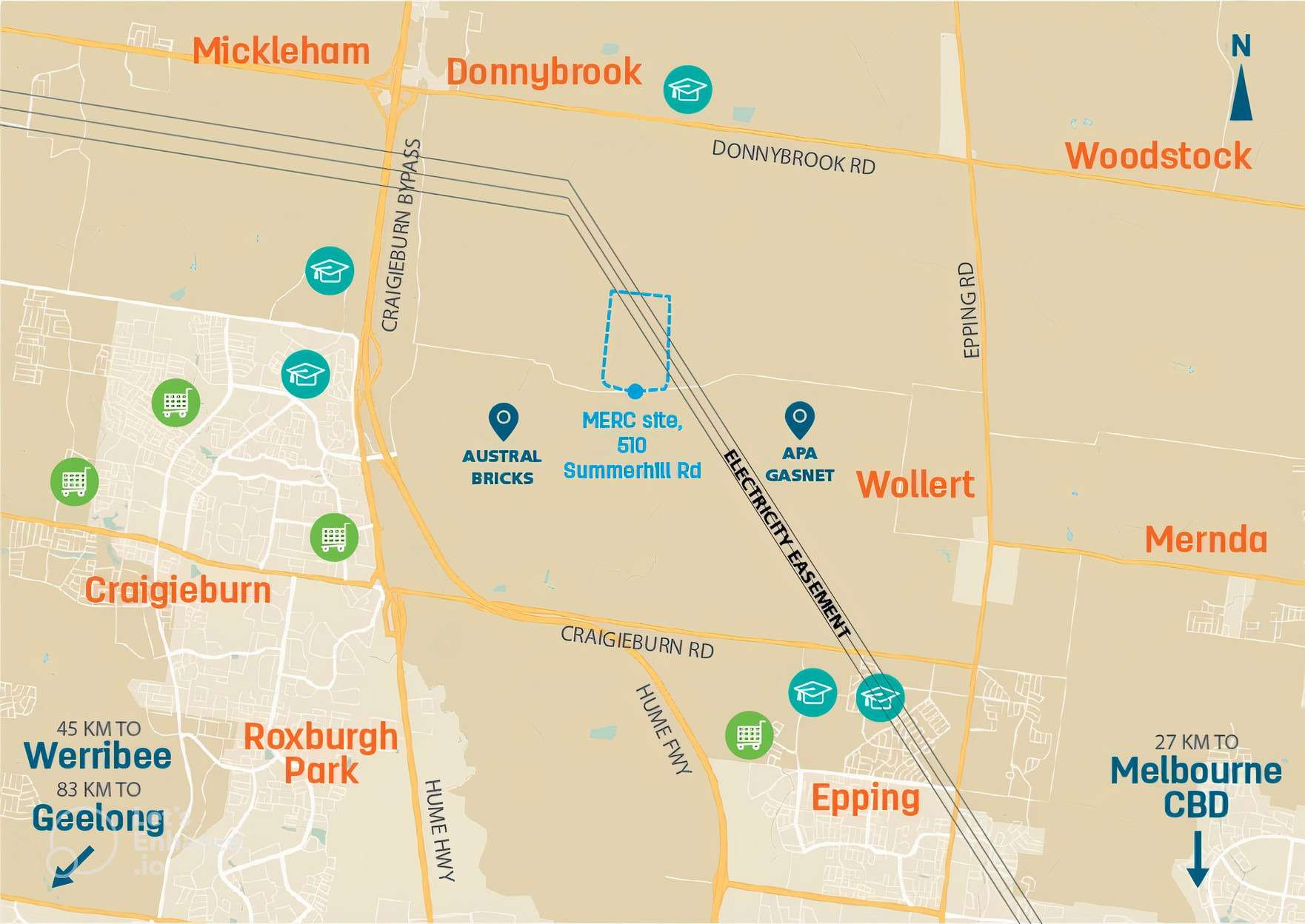

Where is it proposed?

The proposed location for the Melbourne Energy and Resource Centre (MERC) is 510 Summerhill Road, Wollert, Victoria. Click here to view on Google Maps.

Image: A map showing the location of MERC

What will it look like?

We are currently undertaking the technical assessments to inform the design of the MERC. Further details will be shared as it becomes available.

An artist’s impression drawing of the proposed MERC

An artist’s impression drawing of the Visitor and Education Centre as part of the proposed MERC

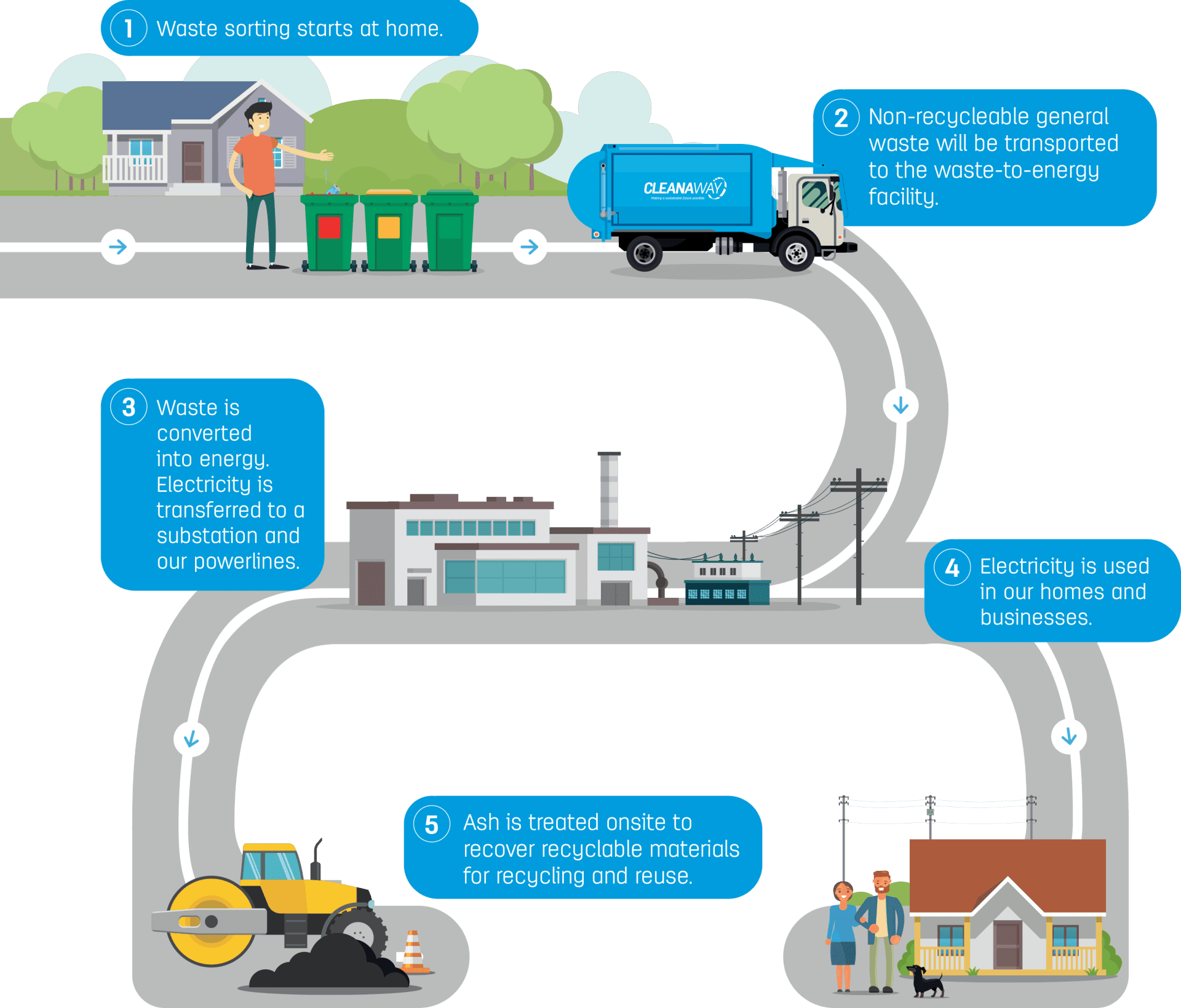

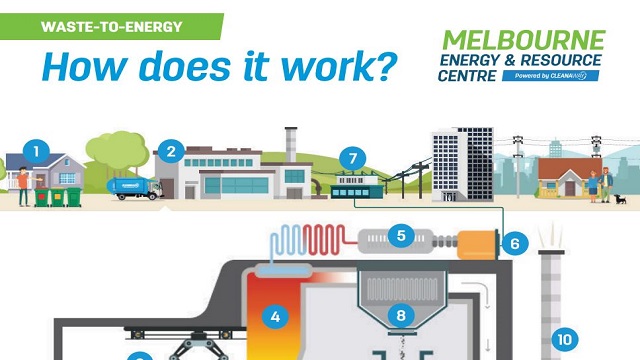

How does it work?

Here are the steps of waste collection and treatment of residual waste.

Read the ‘How does it work’ fact sheet to learn more.

Project timeline (indicative)

In mid-2023, Cleanaway submitted the necessary applications for the MERC proposal to the Victorian Government. If the proposal is approved, it will take approximately three to four years to build the facility.

Learn more about the proposal

Landfills take up vast areas of land and bury useful resources. The Victorian government is taking steps to increase the recovery of materials currently being sent to landfill such as Food Organics and Garden Organics, as part of the Victorian Government’s circular economy policy and plan. However, there will always be waste that cannot be avoided, reused or recycled. For that reason, the Victorian circular economy policy and plan acknowledge the role of waste to energy, for the recovery of energy and other resources from residual waste, through the Victorian Waste to Energy Framework. Cleanaway operates a range of recycling programs and facilities to divert waste from landfill. Through the MERC, Cleanaway is investing in a sustainable alternative to landfills for this residual waste.

*Source: Sustainability Victoria. 2022, September 16. Victoria’s Waste Projection Model.

Residual waste is the general waste we put in the bin after we have reduced, reused and recycled. It also includes residual commercial waste from industrial and demolition sources. Currently, all of Victoria’s residual waste is being sent to landfill for disposal.

Cleanaway is committed to developing safe facilities across Australia.

Our proposal will use international best practice technology to comply with Environment Protection Authority (EPA) Victoria’s standards for air emissions and the European Industrial Emissions Directive, which is based on decades of experience and safe operating practices.

99.9% of the flue gas produced will be gases common to air, including oxygen, carbon dioxide, nitrogen and water vapour. The remaining pollutants will be treated with modern technology to meet stringent emission limits.

We will be publishing air quality monitoring data on our project website on a regular basis.

The proposal will use tried and proven moving grate combustion technology. Moving grate combustion technology is a flexible and robust technology that is best suited for processing mixed waste.

Click here to see how Gloucestershire Energy from Waste Facility (UK) uses this technology.

With over 100 years of operating experience, the moving grate combustion system is used in the majority of international waste-to-energy facilities and has a long track record of reliable operation recovering energy and other resources from mixed wastes.

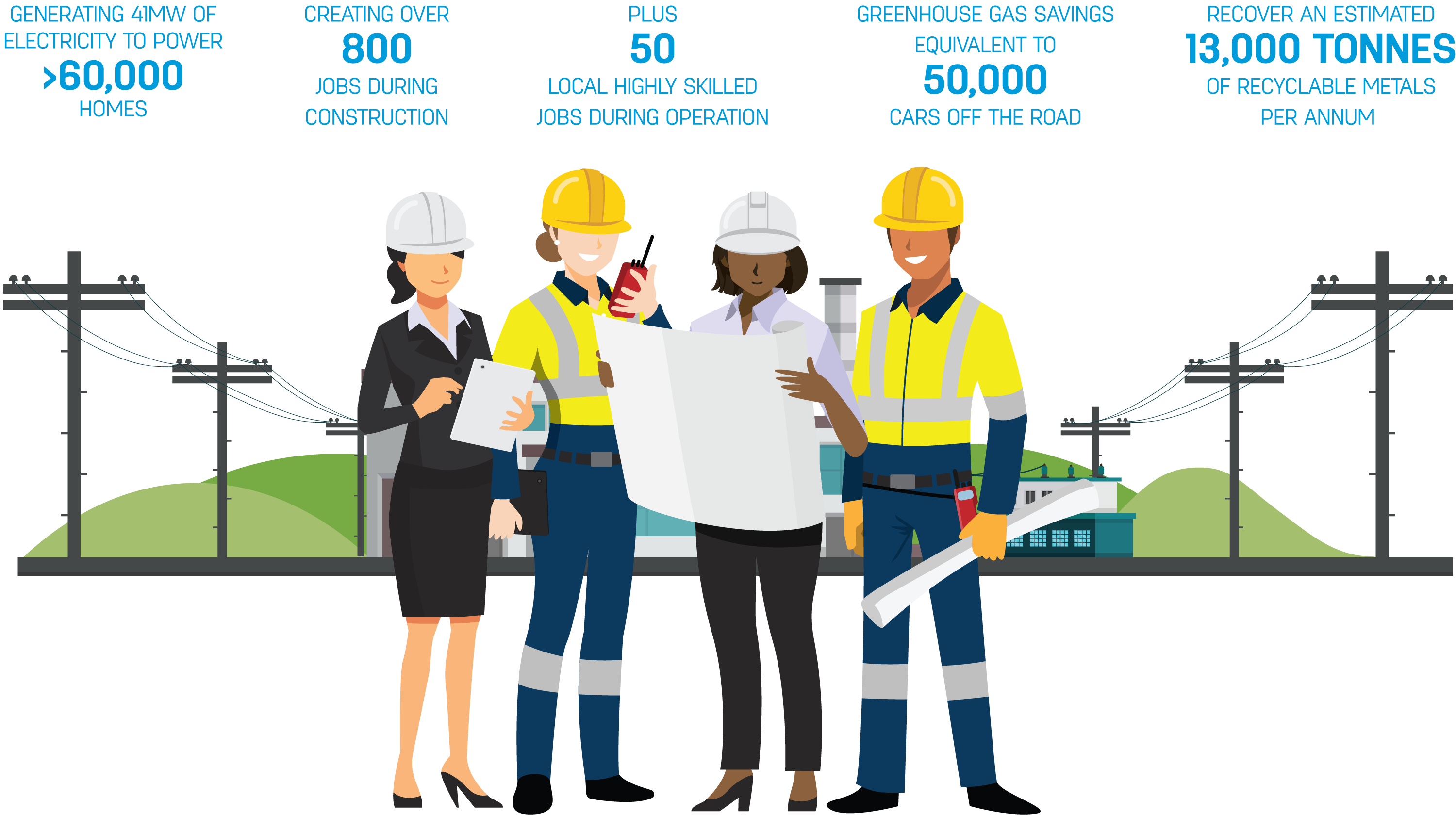

The process will recover an estimated 13,000 tonnes of recyclable metals per year and generate over 40 megawatts of electricity that will power over 60,000 homes.Read the ‘How does this work?’ fact sheet to learn more.

The proposal will avoid methane emissions from landfill and replace electricity that would otherwise be produced from burning fossil fuels. This, along with recovered recyclable metals and construction aggregate, results in an overall net reduction of greenhouse gas emissions.

Of the ~500 waste to energy facilities currently operating in Europe and the UK, the majority are using ‘moving grate’ combustion technology, which is what we are proposing. It is considered to be a safe smart city technology.

The waste hierarchy preferences higher order solutions for the waste we generate.

Our priority is to avoid producing waste in the first place. Where this is not possible we seek to reduce the amount of waste created and then to pursue the highest order “reuse, recycling and recovery options” available in order to prolong and preserve the value of our finite resources at their highest value.

Cleanaway supports Victorians by operating many waste recycling services in Victoria. We recycle food and garden organic waste, glass, paper, cardboard and plastic. Cleanaway also invests in education programs and supports innovative ideas to reduce waste.

To better manage waste, we need to find ways to work at higher levels of the waste hierarchy. The Melbourne Energy and Resource Centre (MERC) proposal aims to do this by recovering energy from residual Municipal Solid Waste (general household waste bins), and residual Commercial and Industrial waste that would otherwise be disposed in a landfill.

Cleanaway has been providing waste management services for over 50 years. We understand the pressing need to reduce the volume of waste that ends up in landfill.

Cleanaway provides a complete range of waste management solutions across Victoria. We also operate the Melbourne Regional Landfill located in Ravenhall. We understand landfills will no longer be a viable option for waste management in the future. Cleanaway supports Recycling Victoria’s policy of reducing waste disposed to landfill. Even after the avoidance of waste, removal of recyclables and food and organics from general waste, Victorians will still be sending over three million tonnes of waste to landfills each year if alternative solutions are not implemented.

The proposed waste-to-energy facility, MERC, will receive residual waste that would otherwise go to landfills. This waste will come from general waste disposed in bins at homes, businesses, shopping centres and schools. The residual waste typically includes items such as packaging materials, nappies and sanitary items, tissues, small bits of wood, broken non-electrical kitchen items, worn out clothing and other general household waste.

The flexibility of the MERC design allows us to preference the waste hierarchy and accommodate future improvements and innovations in waste management practices as Victoria transitions to a circular economy.

Cleanaway provides a complete range of waste management solutions across Victoria. We also operate the Melbourne Regional Landfill located in Ravenhall. We understand landfills will no longer be a viable option for waste management in the future. Cleanaway supports Recycling Victoria’s policy of reducing waste disposed to landfill. Even after the avoidance of waste, removal of recyclables and food and organics from general waste, Victorians will still be sending over three million tonnes of waste to landfills each year if alternative solutions are not implemented.

The proposed waste-to-energy facility, MERC, will receive residual waste that would otherwise go to landfills. This waste will come from general waste disposed in bins at homes, businesses, shopping centres and schools. The residual waste typically includes items such as packaging materials, nappies and sanitary items, tissues, small bits of wood, broken non-electrical kitchen items, worn out clothing and other general household waste.

The flexibility of the MERC design allows us to preference the waste hierarchy and accommodate future improvements and innovations in waste management practices as Victoria transitions to a circular economy.

Who we are

The project is being delivered by Cleanaway, with technical support from Arup, Ramboll and Tract. An indicative project timeline is outlined below.

Ramboll is recognised as one of the world’s leading waste-to-energy engineering consultants. They have 90 dedicated waste-to-energy project managers and specialists, with in-depth knowledge of processes, world-leading technologies, suppliers and facility operations. Ramboll has designed over 150 waste-to-energy facilities in 45 countries, including Australia’s first facility in Western Australia. |

A global leader in waste-to-energy and recovery of resources, Arup is an independent firm of designers, planners, engineers, consultants and technical specialists, working across every aspect of the built environment. Together they help our clients solve their most complex challenges – turning ideas into reality as we shape a better world. |

Tract is facilitating the planning approvals for MERC. Tract has been a trusted consultant to the development industry and to government for the past 50 years. Our Victorian planning team comprises more than 50 professionals and has experience in all forms of development facilitation, assessment and advocacy, and strategic land use planning As planners and designers, our charter at Tract is to deliver sustainable and memorable solutions, shaping places for living, leisure and work, and the infrastructure that supports and connects these places. |

Latest News

| Date | Details |

|---|---|

| 30-10-2024 |

|

| 11-09-2024 |

|

| 01-07-2024 |

|

| 13-6-2024 |

|

| 05-04-2024 |

|

| 25-3-2024 |

|

| 19-3-2024 |

|

| 04-3-2024 |

|

| 18-9-2023 |

|

| 1-5-2023 |

|

| 30-3-2023 |

|

| 6-2-2023 |

|

| 5-12-2022 |

|

We welcome all questions and are here to answer them. If you cannot find the answer to your question in our document, or would like to know more about the project, please let us know.

Or call the Project Hotline on (03) 9021 0603

Discussion board

See what questions are important to your community

| Questions | Our response |

|---|---|

| HI, Could you give me a clearer indication on the map where this plant will be built. Seems very close to housing and does not explain entry points to the plant. Why this isn’t being built at the wollert tip is another question. Look forward to your response | Thank you for your enquiry.

The separate entry points for heavy and light vehicles to the facility will be off Summerhill Road. General waste will be transported by trucks to the waste-to-energy facility via Summerhill Road. Light vehicles (cars etc) will access the site from a dedicated access point to ensure cars and trucks are separated. The location of the site is 510 Summerhill Road. The nearest residential areas are Shenstone Park Precinct, Mickleham, Craigieburn, Epping and Wollert, which are about 1.2 km to 2km away from the site. There are a few nearby residents living along Summerhill Road. They are aware of the proposal and Cleanaway has been in regular communications with neighbours to brief them on the proposal. We understand your concerns that this may seem close to residents. However finding the right location has been a key consideration for this project. Cleanaway undertook a diligent assessment of over 200 potential sites in Victoria and determined that this location is suitable due to its direct neighbours, and proximity to residential and industrial neighbours. The facility will take up approximately 24 hectares (Ha) of the overall 82 Ha purchased by Cleanaway. Of this, only around 10 hectares will be buildings, roads and hardstand. The remainder of the land will provide significant buffers. Additionally, we note that there are other buffers already adjoining the site associated with neighbouring activities such as quarries, future sewer treatment works, potential future power station., and existing industrial facilities such as the Brickworks factory. Many waste-to-energy facilities in Europe and Japan have been built at the centre of the city often only a few hundred meters or less away from residential buildings. Cleanaway has selected this location within an industrial area and away from residential centres. The Wollert landfill is owned and operated privately by another waste company unrelated to Cleanaway. |

| Hello Just wondering if you are planning a similar project in QLD & if so, what are the potential locations? Regards | Thanks for your interest. Cleanaway are in the process of securing a site for a proposed project in Southeast Queensland. More information on this will be provided in the coming months. |

| Illegal dumping of hard rubbish is, sadly, a common problem in the outer suburbs. Will MERC be accepting this rubbish? | We hear your concerns. It’s possible but not that simple. The MERC has a stringent Waste Acceptance Protocol – it only accepts waste that is suitable for energy recovery, rather than recycling; and does not contain materials that are unsuitable for thermal treatment. If the illegally dumped hard waste meets these conditions, and being collected and brought to the MERC, then they can be processed for the recovery of energy and other resources (such as recyclable metals). |

| There have been many waste fires in Melbourne in the last decade which have resulted in terrible pollution and impacts on waterways. What methods and processes would MERC use to prevent adverse impacts on waterways and the local environment of emergency and unplanned events? | Thanks for your question! Our technical team has provided some insights to your question. The MERC will actually help to prevent such fires and their impacts on waterways and the local environment. Those impacts have typically arisen from contaminated firewater runoff resulting from the fighting of fires associated with stockpiles of waste materials, which are often stored outdoors or in warehouses. At the MERC, waste is delivered by truck and deposited in a waste bunker for temporary storage (typically only for a few days). In the waste bunker, the waste is constantly mixed by a grab crane and actively monitored for hot spots. Firewater canons are present in the bunker area to deal with hot spots and extinguish any fires that may occur in the bunker. The waste bunker will be indoors and will have sealed concrete walls and foundations, such that any firewater will be retained within the bunker. |

Cleanaway agrees that the best way to treat waste is still to avoid, reduce, re-use and recycle whenever possible. Victorians are getting better in sorting and diverting recyclables, food and organics to recycling/composting facilities. However, there will always be things that cannot be recycled (such as items that are put in the general waste bins, or commercial and industrial waste). At the moment, these non-recyclable items end up in landfill – currently around 4.6 million tonnes each year in Victoria (refer to Sustainability Victoria’s waste projection model and select the year 2022).

Cleanaway is finding new ways to make good use of non-recyclable materials. We have learnt from international experience that waste-to-energy technology can help us recover energy and largely reduce the need for landfills.

99.9% of the flue gas produced will be gases common to air, including oxygen, carbon dioxide, nitrogen and water vapour. The remaining pollutants are treated with modern technology to meet stringent emission limits. On cold mornings you may observe a white mist coming from the flue gas stack that is caused by condensing water vapour.

Continuous Emissions Monitoring Systems (CEMS) will be used to continuously monitor the quality of flue gas emissions from the MERC to provide feedback to the flue gas treatment control system and for reporting purposes.

By proposing to utilise best available techniques throughout the MERC facility, the proposal will benefit from the vast amount of knowledge and experience that has been gained internationally in designing, constructing, commissioning, operating and maintaining a state-of-the-art waste-to-energy facility that meets best practice performance and environmental emission standards. Those standards have been developed over the past decades based on operating facilities in Europe and the UK, and have been established to protect human health and the environment. This is important because in Europe and the UK, most of the waste-to-energy facilities are located in the middle of major cities and without the luxury of buffer zones (that is as close as possible to where the waste is generated and where the energy and other resources recovered from waste can be readily utilised.)

The MERC will be designed to meet the EU Industrial Emissions Directive 2010/75/EU (IED), which sets stringent emission limits and monitoring requirements. In addition, the MERC will include on-site processes to treat the solid ash residues, to either enable their reuse, or their safe disposal to landfill.

Cleanaway takes its environmental protection duties very seriously and has engaged specialists to undertake an Air Quality, Greenhouse Gas, Odour and Human Health assessments to identify any potential adverse impacts to the surrounding community and to ensure that the process design and any proposed mitigation measures will be effective in avoiding the risk of environmental damage and/or impacts on human health.

Cleanaway undertook a diligent assessment of potential sites and determined that this site is the most appropriate due to the buffer distances to residential and industrial neighbours.

The site in Wollert was selected as the most appropriate location, after a thorough search of alternatives across Victoria. Our proposed waste-to-energy facility takes up about 10 hectares of our overall 82 hectare site (plus supporting infrastructure)

The site was selected with the existing neighbours in mind, as well as the future proposed developments surrounding the site. The site is located near an existing and (approved) future quarry, high voltage electricity transmission lines, a future wastewater treatment facility, a proposed gas-fired power station and the existing Brickworks brick-making plant and quarry.

We are in regular communication with neighbours to reduce any potential impacts from the facility.

Our proposal is designed to use international best practice technology to ensure that there is no adverse impact to the environment.

As part of the environmental approvals for the project, we are undertaking air quality modelling, as well as a human health risk assessment to further understand potential risks.

The development of the MERC is sponsored by the private sector. Proposed development costs are in excess of $700m.

Once the MERC is operational, waste suppliers such as councils (who collect household waste from rate payers), businesses and institutions who use Cleanaway’s waste collection services and third party commercial waste collection service providers will pay a fee to have their residual waste processed at the MERC, just as they currently do to send that waste to landfill for disposal.

The MERC will create over 800 direct jobs in construction and even more indirect jobs. It will create 50 ongoing highly skilled jobs.

The MERC will include a Visitor and Education Centre to increase awareness of the waste hierarchy and promote ways to reduce, reuse, recycle and recover energy (and other resources such as recyclable metals and construction aggregate) from waste. We welcome local schools, community groups and individuals to reach out to discuss future opportunities for visits and to develop educational programs.

The inert bottom ash (known as Incinerator Bottom Ash) will be allowed to mature before it is processed to separate metals for recycling and to create an aggregate product (IBAA). It is common practice in the UK and Europe for the IBAA to be utilised in construction applications. By recovering recyclable metals and reusing the IBAA, we will be able to divert more than 95% of waste from landfill!

The Air Pollution Control residues (APCr) may have relatively high concentrations of heavy metals and typically requires treatment prior to disposal at a licenced landfill. At the proposed MERC facility, APCr is collected in sealed silos so that no ash escapes. It is then treated onsite to immobilise pollutants into cement-like blocks, before the solidified ash is disposed of at an appropriate landfill.

You can read the “Ash and residue management” fact sheet to understand more.

Cleanaway, through its network of transfer stations and Melbourne Regional Landfill, understand the volume of waste that is currently disposed to landfill. A thorough assessment of waste volumes in the Melbourne market has been undertaken to inform the setting of the design capacity of the MERC facility and to ensure that there is sufficient waste available to make the facility viable. All waste that the facility is proposing to take is waste that will be diverted from landfill.

Cleanaway is working with the Traditional Owners, the Wurunjderi Woi Wurrung People, to develop this project. Wurunjderi Woi Wurrung have recently been onsite with our Heritage Consultants conducting detailed investigations as part of our Cultural Heritage Management Plan.

Since 2018 Cleanaway has been developing a proposal to construct a waste-to-energy (also known as energy-from-waste in Sydney) facility in Western Sydney before the NSW Government released their waste-to-energy policy in 2021. The new “Energy-from-Waste Infrastructure Plan” limits the development of waste-to-energy facilities to four Priority Infrastructure Areas, all of which are located outside the Sydney Basin, unless they meet certain criteria where the waste feedstock is a substitute to other fuels.

Cleanaway is considering the new Infrastructure Plan to find a way forward for its project that is consistent with the plan.

Cleanaway believes that waste-to-energy plays a key role in the waste value chain and transitioning to a circular economy. It provides a long-term solution for waste that cannot be diverted from landfill and delivers a superior environmental solution to landfill. Our Western Sydney project has always been proposed to meet and exceed the most stringent global emissions standards for waste-to-energy.

Cleanaway has gained significant experience in developing the Western Sydney project proposal and we are bringing these learnings into developing the MERC proposal for Victoria.

In Europe and the UK, waste-to-energy facilities are commonly referred to as “waste incinerators”. The Industrial Emissions Directive (IED) defines ‘waste incineration plant’ as “any stationary or mobile technical unit and equipment dedicated to the thermal treatment of waste, with or without recovery of the combustion heat generated, by oxidation of waste as well as other thermal treatment processes.”

The word “incinerator” may remind people of the uncontrolled burning of waste for disposal. People may have memories of heavily polluted facilities that were used in the past.

The MERC will use moving grate combustion technology, for thermal treatment of waste by complete oxidation of the waste. The MERC will be classified as a ‘recovery’ process (rather than ‘disposal’), because the moving grate combustion system is integrated with a boiler to recover the heat of combustion in the form of high pressure steam to generate electricity. Flue gas from the combustion systems will be treated to remove pollutants using advanced flue gas treatment technology. This will allow the MERC to meet European air emission standards, which is adopted by the Victorian Environment Protection Authority.