It takes a collective approach to drive change

At Cleanaway, sustainability isn’t just part of what we do, it’s who we are. Our purpose – “making a sustainable future possible together” guides every decision, from the way we serve our customers to how we invest in people, protect the environment, and drive innovation across our business.

With over 50 years of experience, a team of 10,000+ skilled people, 6,400+ vehicles, and a national network of 350+ sites, Cleanaway has the scale, systems, and expertise to deliver real impact. Every day, our teams recover valuable resources, reduce emissions, and help communities thrive because we believe waste is a resource with the power to create positive change.

Explore how our commitment to sustainability, health, safety, environmental leadership, and ethical business practices sets us apart and why partnering with Cleanaway means building a better future together.

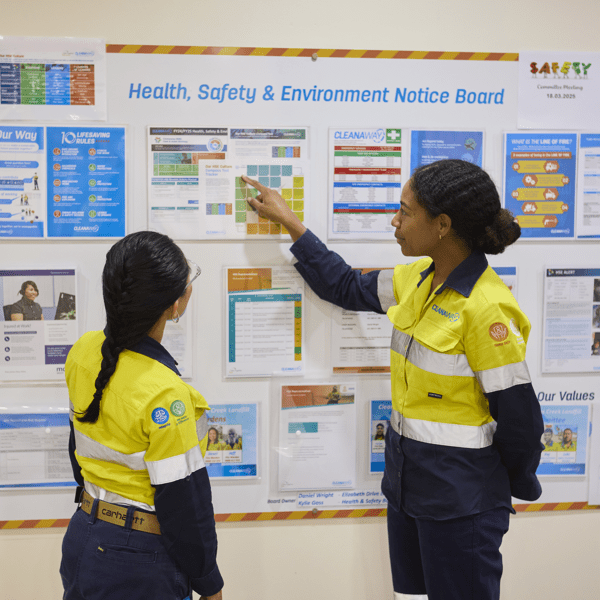

Health, Safety and Environment (HSE)

Discover our vision to lead the industry in safety and environmental performance – the very foundations of how we operate.

Sustainability at Cleanaway

Learn about our Sustainability Framework and why creating positive outcomes for the environment, our people, and our communities is at the heart of everything we do.

Our fleet

We have one of Australia’s biggest fleets – that’s why we’re working to actively decarbonise it. Discover the innovative and impactful ways we’re doing just that.

Communities

Learn about our grassroots involvement with the local communities we serve, through sponsorships, donations, partnerships, and events.

Education

Find out how we support people and organisations to manage waste disposal correctly through our education programs – and why this is important.