About

Industrial solvent washers

for parts cleaning and degreasing

Cleanaway’s solvent sink service offers a total cleaning, waste removal solution for workshops and manufacturing facilities that work with oily and grimy mechanical parts.

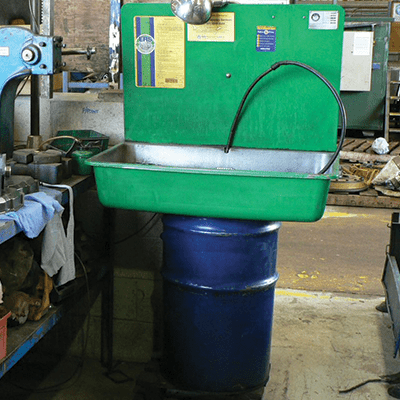

Solvent sinks are convenient bench-mounted systems for manual cleaning and degreasing of small to medium-sized mechanical parts. Using petroleum or citrus-based cleaning solvents, they can break down stubborn contaminants to leave parts clean, dry and ready for use.

When you buy or rent our solvent sinks, you’re supported by a complete service package that includes regular delivery of fresh solvent, safe removal and recovery of used solvent where possible, and ongoing maintenance.

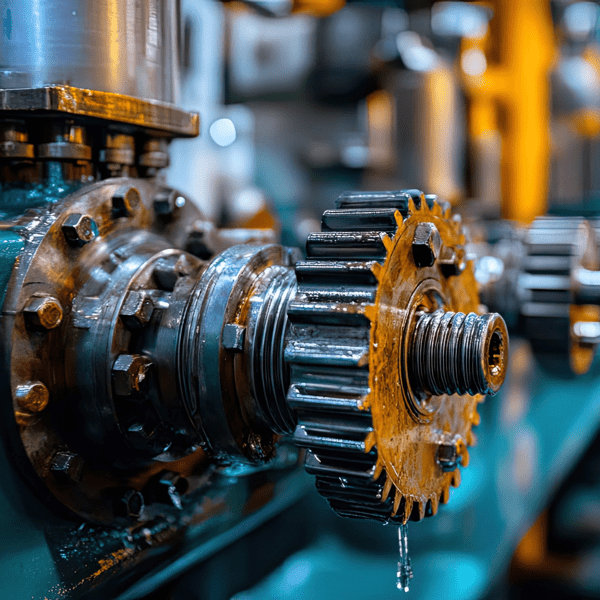

hether you’re cleaning engine parts, bearings, gears or tools, our degreasing sinks can help to keep your workshop clean and efficient.

Parts cleaning and degreasing

Safe, enclosed sink units for cleaning mechanical parts using recycled solvent to dissolve grease, oil, adhesives, and tough industrial contaminants.

Solvent recovery and replacement

Regular servicing to remove used solvent, recover and recycle it where possible, and replace with fresh solution for ongoing cleaning performance.

Service

Who uses our

solvent sink parts washers

Cleanaway’s solvent sink services are ideal for workshops and maintenance teams that handle regular mechanical cleaning tasks, including:

Automotive and vehicle workshops

Cleaning and degreasing parts during regular servicing and repairs of light and heavy vehicles

Industrial maintenance teams

Removing oil, grease and grime from equipment and their components

Fleet and logistics operations

Removing contaminants to keep vehicle parts and machinery in optimal working condition

Engineering and fabrication workshops

Preparing metal and other materials for assembly, coating or welding

![]()

Process

How Cleanaway’s solvent sinks and services work

Cleanaway offers a comprehensive cleaning, maintenance, waste removal and recycling service for solvent sinks and their waste products.

Cleanaway technicians schedule regular servicing to top up fresh solvent, remove spent solvent, and inspect, clean and repair the system.

Details

Solvent sink features and benefits

Cleanaway’s Australian-made solvent sinks are built for safety, convenience and effective manual cleaning and degreasing, with models to suit any workshop or manufacturing facility.

6 gauge cold rolled steel construction and central drum mounting for strength and stability under large loads

Fast solvent flow rate of ten litres per minute for efficient cleaning

Three-stage filtration system producing cleaner solvent for reuse

Easy mobility for flexible placement within your workspace

![]()

Output

Solvent recycling and disposal

Used solvent is hazardous waste that requires specialist handling. Cleanaway safely collects and transports solvent waste to EPA-licenced treatment facilities where it’s either recovered for recycling or disposed of in line with environmental regulations.

Our aim is to recover and reuse solvent wherever possible. If it’s a type of solvent that can be recycled, it undergoes a distillation process to break it down into its component parts. This material can then be made into new solvent or other uses. Through this recovery process, Cleanaway is able to close the loop on solvent waste and keep reusable solvents in use.

Our promise

Why choose Cleanaway

-

A one-stop solution

We offer an expansive range of services, custom waste solutions and expert support to meet the waste management and resource recovery needs of Australian businesses, councils and industries of any size.

-

Optimised waste management solutions

Our team of resource recovery professionals work closely with you to find the best waste management solution for your business, helping you achieve potential cost savings while working towards your sustainability goals.

-

Streamlined services

We offer a total waste management solution, providing you with seamless customer service, one invoice and consistent, reliable services.

-

Nationwide service you can count on

With a vast national network of specialised facilities and one of the largest waste collection fleets on Australian roads, we deliver efficient and reliable service across most of Australia.