![]()

About

Save time and money

with industrial hot tanks

If you’re dealing with high volumes of heavily greased or carbon-contaminated machinery parts, hot tanks deliver a powerful, automated cleaning method that could reduce labour time, chemical use and overall cleaning costs.

Cleanaway’s hot tanks offer industrial-strength cleaning through a heated chemical solution that strips contaminants from metal components. This fast and effective one-step method removes heavy build-up from both internal and external surfaces, making it ideal for hard-to-reach areas and large, heavily soiled parts that need more than manual scrubbing or water-based systems. It’s maximum cleaning performance with minimal manual effort.

Trusted by automotive, manufacturing and heavy industry businesses across Australia, our hot tank service is a reliable solution for degreasing, descaling and removing carbon build-up from parts.

Hot tank parts washers are available for sale or rent, with full servicing and maintenance included, as well as disposal of the used cleaning fluids in compliance with EPA guidelines. We take care of all the parts washing logistics so you can focus on the job, not the clean-up.

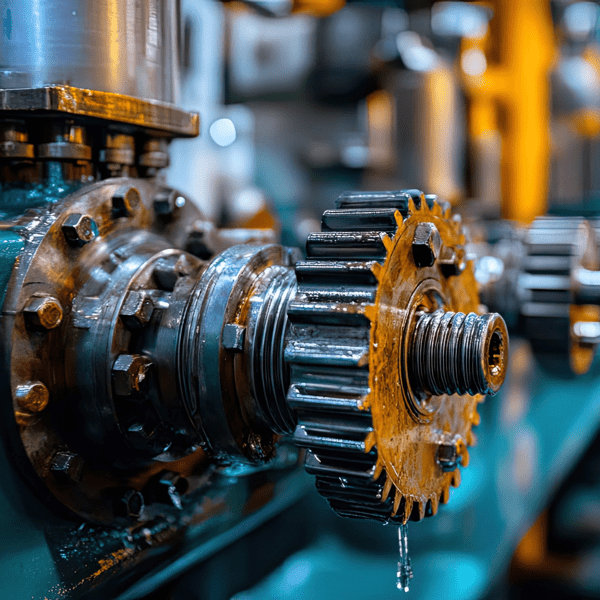

Grease, oil and carbon build-up

Safely removes baked-on grease, carbon deposits, and petroleum-based contaminants from engine parts, machinery components, steel tools and industrial tools.

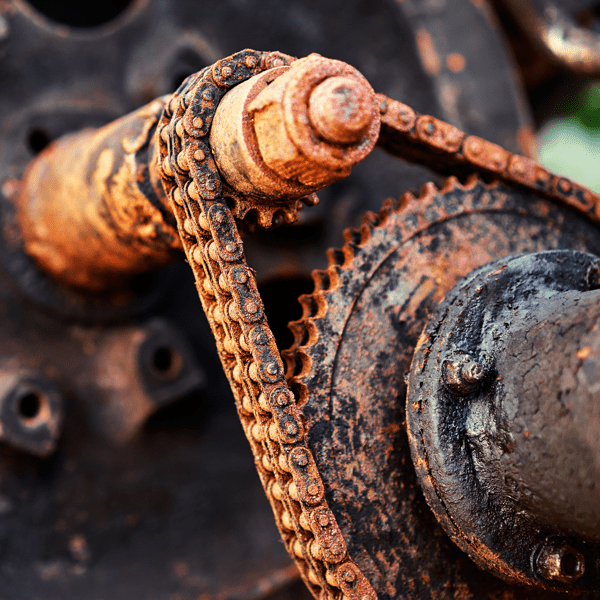

Rust, paint and coatings

Dissolves rust, old paint layers, powder coatings, and protective films from metal parts, restoring surfaces for repair, refurbishment, or recoating.

Service

Who uses our hot tank service

Our hot tank service is purpose-built for industries with high-throughput mechanical degreasing and cleaning requirements, including:

Automotive and diesel workshops

Remove oils, grease, and carbon from engine blocks, gearboxes, brakes and injectors

Heavy vehicle and fleet maintenance

Degrease transmissions, suspension parts and heavy-duty engine components

Rail, mining and heavy industry

Clean dirt, grease and debris from mining equipment, hydraulics and large mechanical parts

Mechanical engineering and manufacturing

Keep tools, machine parts and welding gear in optimal condition by preventing built-up of contaminants

Service

Benefits of using an industrial hot washer

Cleanaway’s new generation chemical cleaning system supports workshop efficiency, reduces operational costs and improves sustainability.

Time efficiency

Hot tanks clean heavily soiled parts in 60–120 minutes, with filter cleaning taking just 15 minutes a week. Automation minimises manual labour, providing potential boosts to productivity as workers can perform other tasks during the cleaning process.

Cost savings

In addition to the cost savings that can result from automation, the hot wash system can extend the life of cleaning chemicals, reducing the need for top-ups.

Decreased chemical use

Efficient waste separation via the centrifugal filter and reduced chemical use reduces hazardous waste production. Our waste handling and disposal prioritises environmental protection.

Deep cleaning of engine parts

Hot tanks use heated chemical solutions to quickly dissolve contaminants and reach areas manual cleaning or spray washers can’t. Clean, contaminant-free surfaces are essential for precision work like cutting, shaping and finishing parts, ensuring new components fit and seal as intended

Details

How Cleanaway’s hot tanks

and services work

Hot tank set-up

We deliver and install the hot tank system to your workshop or service site, and provide on-site staff training and risk assessment.

Loading and immersion

Dirty equipment is loaded into the hot tank without pre-cleaning. Parts are submerged in a heated chemical solution to break down oil, grease, rust and carbon deposits.

Agitation

The solution is agitated, which helps to dislodge build-up from internal and external parts surfaces.

Rinsing and drying

Parts are rinsed to remove any remaining chemical solution or loosened debris, emerging clean, dry and ready for inspection, machining or reassembly.

![]()

Process

Hot tanks technology and features

Details

Hot tank product specifications

Cleanaway’s heavy-duty degreasing tanks come in seven different sizes – with loading ranges from 200 litres to 22,000 litres to accommodate both small and large mechanical parts. Designed by end-users for optimum performance, our agitating chemical cleaning systems are proven to remove heavy build-up of carbon, grease, oil and rust from all surfaces.

Key features and benefits of Cleanaway’s hot tanks:

- Waste solids from the centrifugal filter can generally be disposed of in an industrial waste bin, reducing the chemical waste that requires specialised collection and treatment

- No sludge settlement area, reducing tank volume and initial chemical fill by 30%

- Optional rinse bay that attaches to the tank to reduce spillage

- Pneumatic lid lift can be automatic with a platform lift or independent of the platform for servicing

- Each machine comes with an installation, operations and maintenance handbook complete with servicing diagrams and electrical circuits

- Made in Australia

Output

What happens to hot tank waste

Cleanaway manages the complete waste lifecycle of your hot tank parts washer including:

Collection of used cleaning solution from your site

Transport in licensed vehicles to EPA-compliant liquid waste treatment facilities

Safe treatment and neutralisation of hazardous residues

Wastewater recovery where possible or alternative safe disposal

Our promise

Why choose Cleanaway

A one-stop solution

We offer an expansive range of services, custom waste solutions and expert support to meet the waste management and resource recovery needs of Australian businesses, councils and industries of any size.

Optimised waste management solutions

Our team of resource recovery professionals work closely with you to find the best waste management solution for your business, helping you achieve cost savings while meeting your sustainability goals.

Market-leading infrastructure

Our EPA-licensed, state-of-the-art facilities enable safe, efficient waste processing and resource recovery at scale.

Making a sustainable future possible together

We’re leading the way in sustainable waste management and resource recovery, helping Australia to transition to a circular economy and investing in lasting solutions for the benefit of all Australians – now and into the future.