About

Why choose Cleanaway’s

high-pressure water blasting services

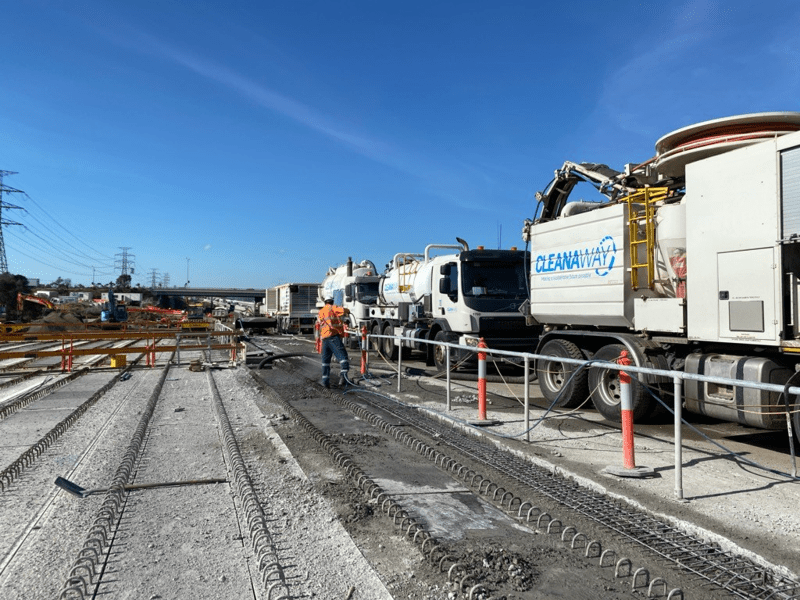

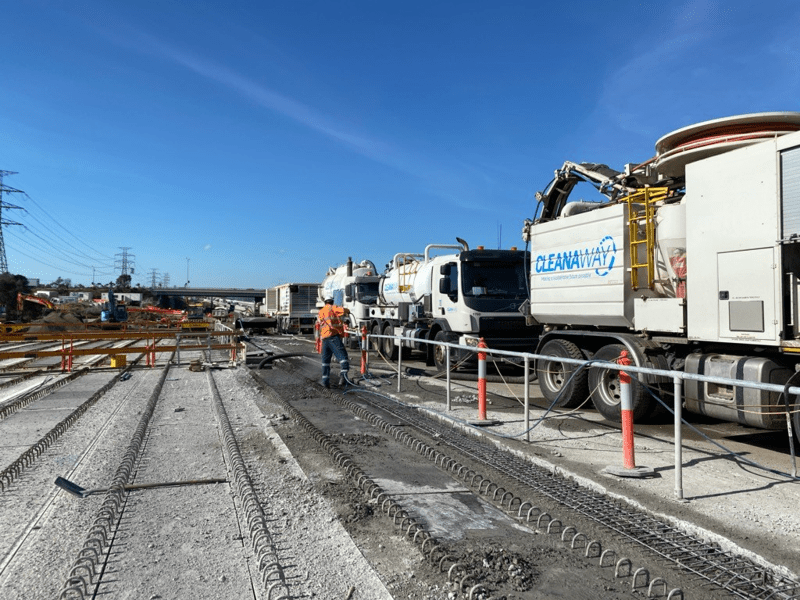

Cleanaway is the industry leader in all facets of high-pressure and ultra-high-pressure (UHP) water jetting, delivering working pressures of up to 60,000 psi through automated, remotely operated and manual systems. Our advanced hydro-jetting technology enables confined-space-free cleaning, multi-lance precision control, and up to 75 per cent faster turnaround times, setting new benchmarks for safety and performance.

Tailored for mining, oil and gas, manufacturing, construction and utilities, our services combine state-of-the-art equipment with highly trained operators to provide efficient, inspection-ready cleaning across infrastructure, mine-sites, refineries, petrochemical plants and industrial facilities.

These capabilities form part of Cleanaway’s integrated Industrial Services offering, strengthened through our integration with Contract Resources.

Safer cleaning in hazardous environments

A non-abrasive, spark-free cleaning method that reduces risk, supports confined-space work and helps customers meet strict safety and environmental requirements.

Minimising downtime, maximising productivity

Deployed by specialist crews using purpose-built equipment to support shutdowns, maintenance programs and unplanned works with speed, control and reliability.

Process

Our high-pressure water blasting and jetting services

Cleanaway provides advanced surface preparation and protective coating services that ensure long-term asset integrity across industrial and energy facilities. Using ultra-high-pressure (UHP) water jetting up to 60,000 psi and automated Spiderjet and Aqua Cutter robotic systems, we deliver precise, dust-free and confined-space-free surface cleaning for tanks, bridges, tunnels and process equipment.

With state-of-the-art equipment, extensive industry knowledge and specialised technologies, we can provide a variety of industrial tank cleaning solutions. This includes Confined-Space-Free Tank Cleaning (CRSRS) and Solid-Liquid Treatment (SLT) technologies, where we eliminate the need for manual entry while reclaiming usable hydrocarbons and reducing waste volumes by up to 80 per cent.

Cleanaway provides automated heat exchanger and tube bundle cleaning solutions that combine safety, precision and productivity. Using hydraulic bundle extractors, multi-lance internal cleaners and remote-controlled external cleaning systems, we deliver up to 75 per cent faster turnaround times with zero confined-space entry or discharge to grade.

Cleanaway delivers specialist cold cutting solutions that combine ultra-high-pressure water jetting with abrasive technology to safely cut through steel, pipework and industrial materials in hazardous or confined environments. Our teams bring deep expertise from refinery, petrochemical, LNG and energy-sector projects, using automated and remote-operated cold cutting systems engineered for locations where sparks, heat or ignition sources are strictly prohibited.

Cleanaway delivers advanced concrete remediation and demolition solutions using ultra-high-pressure (UHP) water jetting and automated robotic systems engineered for precision, safety and minimal environmental impact. Our combined expertise spans refineries, LNG facilities, petrochemical plants and major civil infrastructure, where vibration-free, dust-free and rebar-preserving removal is essential. Using Aqua Cutter and other remote-operated systems, our teams execute highly controlled scabbling, surface removal and structural demolition in confined, overhead and hazardous environments.

Cleanaway provides advanced cleaning solutions for plant equipment and process machinery, combining high-pressure water, mechanical and chemical systems to restore performance and reliability. Using automated and remote-operated cleaning technologies, we remove scale, rust and hydrocarbon build-up from internal and external equipment surfaces including reactors, compressors, turbines, heat exchangers and process vessels.

Details

High-pressure water blasting and jetting services

Details

How high-pressure water blasting can enable resource recovery

By removing contaminants and hazardous buildup, we help return materials like pipes and surfaces to a condition suitable for reuse, contributing to a more sustainable, circular approach.

Our promise

Why choose Cleanaway

A one-stop solution

We offer an expansive range of services, custom waste solutions and expert support to meet the waste management and resource recovery needs of Australian businesses, councils and industries of any size.

-

Optimised waste management solutions

Our team of resource recovery professionals work closely with you to find the best waste management solution for your business, helping you achieve potential cost savings while working towards your sustainability goals.

Market-leading infrastructure

Our licensed, state-of-the-art facilities enable safe, efficient waste processing and resource recovery at scale.

Making a sustainable future possible together

We’re leading the way in sustainable waste management and resource recovery, helping Australia to transition to a circular economy and investing in lasting solutions for the benefit of Australians – now and into the future.