![]()

About Us

Proud history

ASP Plastics is a leading specialist in plastic injection moulding and blow-moulding services. Based in Western Sydney, we have been providing Australian and international clients with bespoke, high-quality solutions since 1960. From humble beginnings as a spring manufacturer before expanding to plastics in 1971, we have grown to become a total solution provider for customers looking for superior, tailor-made products. In 1989, we experienced a pivotal moment when we were asked to partner with the NSW Department of Health in the design of the world’s first personal sharps container, an initiative used globally in the fight against HIV/AIDS.

Customer focused

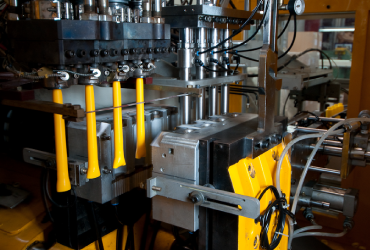

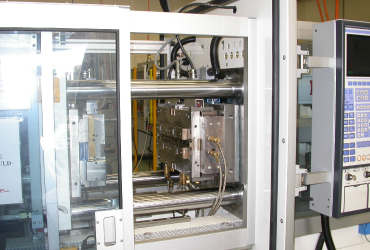

As a trusted industry pioneer, we have an extensive range of automated and robotic injection moulding machines, ranging from 50T to 1300T clamping force. This scale enables us to create practical solutions for our customers, delivering on their specific needs regarding mould size and complexity. As a member of APCO, we are also proud to offer a closed loop solution, with customers able to return used products to us for on-site grinding.

Quality driven

Quality is at the core of everything we do, enabling us to deliver exceptional results and outstanding value to our customers. We operate from a well-equipped, leading-edge tool room, enabling us to conduct modifications and repairs quickly and inexpensively. Our commitment to quality is recognised through the following certifications:

• ISO 9001:2015 Quality Management System certification. • AS4939-2001: Non-reusable personal use containers for collection and disposal of hypodermic needles and syringes. • AS4031-1992: Non-reusable containers for the collection of sharp medical items used in healthcare areas.

Committed

Our experienced team of 80 professionals is dedicated to delivering 24-hour production capabilities. With a commitment to championing diversity, we are proud of our 50/50 gender split across the workforce. As we continue to grow and evolve, we remain dedicated to providing high-quality plastic moulding solutions and exceeding our customers' expectations.

We've been in the business for over 60 years, so it's fair to say we don't just know what we're doing, we excel at it. We have the in-house capabilities to manage the entire development and production process, and our business is formally certified to international quality management standards. You can trust us to create a product that is superior, meets your specific requirements, and is delivered on time, all while adhering to rigorous quality and safety protocols.

![]()

What we do

We offer a range of state-of-the-art moulding, design, assembly, and distribution services, which can be custom-made to fit your needs and timescale - no matter how big or small! From early-stage concepts to fully detailed 2D drawings and 3D CAD models, we can turn your ideas into reality. Our process begins with the creation of 3D CAD models, allowing us to provide you with detailed drawings that ensure precision and control over tolerances. Partner with us to bring your vision to life with exceptional quality and expertise.

Design services

Our highly qualified design engineers offer a unique integration of extensive design experience, combined with making and moulding skills. Our design services are often offered complimentary if ASP undertakes the final moulding process. Where necessary, we can also provide prototype samples to be used for demonstration or proof-of-concept purposes. Available services: 1) Product design; 2) Tooling design; 3) manufacturing Prototyping.

Moulding services

We offer a wide range of cutting-edge machines capable of moulding anything to the required size. We can deliver both an end-to-end moulding service, or provide the components necessary for the customer to mould with their own tool. We also offer a full range of blow-moulding support, including original product design and manufacture of the tooling. Available services: 1) Injection moulding; 2) Blow moulding

Sonic welding

Our wide variety of welding equipment means we offer sonic welding services that can be delivered using manual systems, through to semi-automatic and fully automatic machines that eject products onto a packing line. Whatever your sonic welding needs, we have a solution that can meet your requirements. Available services: 1) Ultrasonic welding; 2) Access to industry experts

Packing and distribution services

Operating on a 24 hours per day, 5 days a week basis, our superior facilities can procure, assemble, warehouse, and deliver products on behalf of our customers, thereby providing a cost-effective solution for businesses without the space, equipment or resources to manage it inhouse. Available services: 1) Packing and assembly; 2) Labelling services; 3)Warehouse and distribution services

![]()

Why choose ASP Plastics

Custom-made solutions

Thanks to our years of experience and cutting-edge equipment, we can create products of any size – no matter how big or small. We will work with you to design a product that exactly meets your specifications, which we can produce inhouse or provide you with the means to create it using your own tools.

Swift, premium service

Need something in a hurry? Don’t worry, our round-the-clock production capabilities will ensure that your product is ready for whenever you need it. And rest assured that we never compromise on quality. Whatever your turnaround time, you can feel confident that it will be made to the highest industry standards.